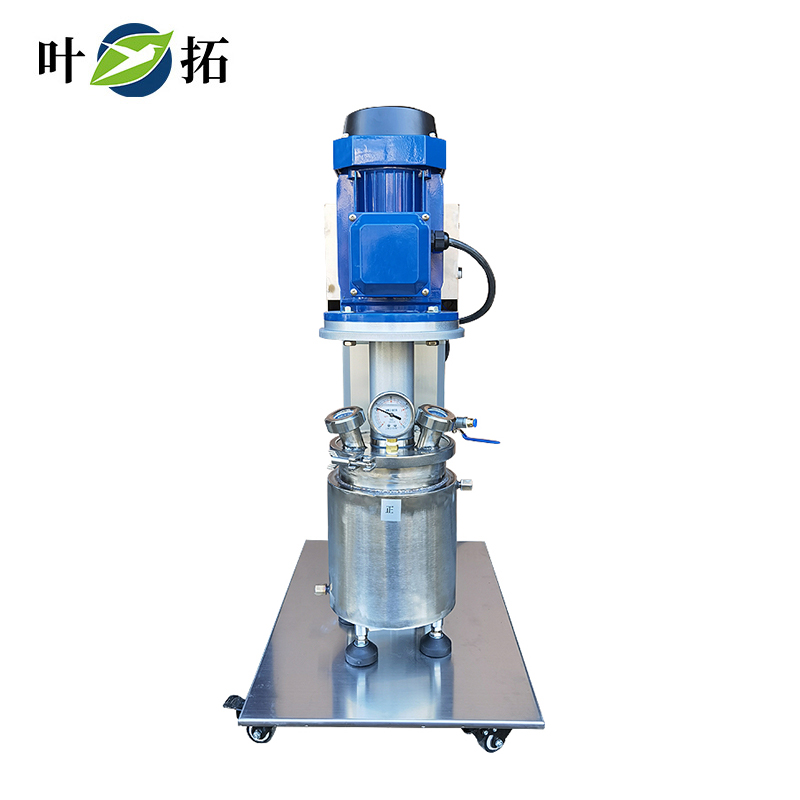

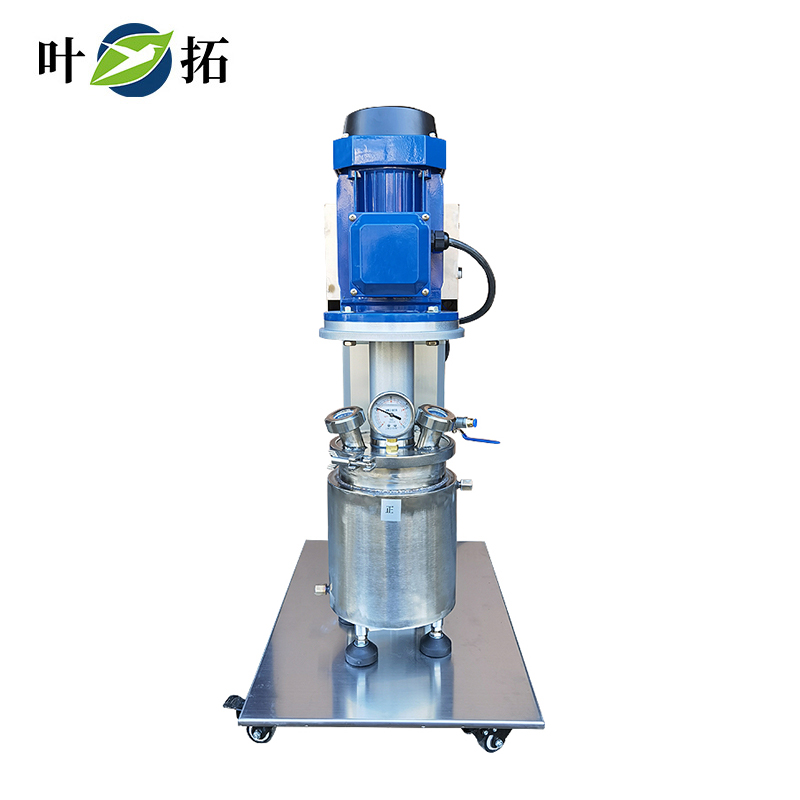

Product parameters:

Model: YTFS-3000

Motor type: three-phase asynchronous

Voltage: 220V

Power: 1100W

Speed: 0-3000R/min

Lifting method: electric

Lifting stroke: 250mm

Processing capacity (kettle volume): 3L

Equipment size: 600 * 400 * 800mm

Bottom plate size: 600 * 400mm

Vacuum degree: -0.095mpa

Disperse disk size: 50mm

Configuration: Pressure gauge, exhaust port, spotlight port, observation window

Note: This model can be customized with parameters and functions according to requirements

- Product Details

- Product manual

Yetuo YTFS-3000 Experimental Vacuum Dispersion Machine

Model: YTFS-3000

Product Overview:

The experimental vacuum disperser is a high-performance product developed by our company, which combines the functions of dispersion/stirring and vacuuming into one device. This device has the ability to disperse/stir in a vacuum environment, avoiding contact between materials and external gases during the mixing process. High efficiency, good mixing effect, easy to clean.

Experimental vacuum dispersers are widely used in factories, research institutions, universities, medical units, and other institutions. It has been widely used in the development and experimentation of products such as pigments, inks, food, coatings, biology, physics and chemistry, cosmetics, etc.

Product features of Yetuo YTFS-3000 experimental vacuum disperser

● Choose variable frequency brushless motor, no sparks/dust, higher safety performance, low noise, sufficient power, can run for a long time, easily meet various high requirements for dispersion and mixing experiments

The part in contact with the material is made of high-quality stainless steel material, which is corrosion-resistant, wear-resistant, and pollution-free

● Adopting wear-resistant/corrosion-resistant mechanical seals for longer service life and better sealing performance

Adopting reinforced sealing rings and clamp fixation design, it is more conducive to the sealing and pressure holding effect of the product, and the kettle body does not undergo displacement when handling high viscosity materials

The dispersing disk is connected to the dispersing shaft using hexagonal screws, making it easy and flexible to disassemble and assemble

Select high-quality electric lifting platform (18 sets of high-frequency modules) for more stable, reliable and durable operation

The base and distribution cabinet are both designed with high-quality stainless steel cladding to avoid cleaning and rusting caused by material contamination during use

The kettle body is made of high-quality stainless steel material, with a sandwich layer and designed with inlet and outlet ports. Facilitating the circulation of water in specific experiments to cool or raise the temperature of materials

Alibaba Store

Alibaba Store Tmall Store

Tmall Store Jingdong Sstore

Jingdong Sstore